Description

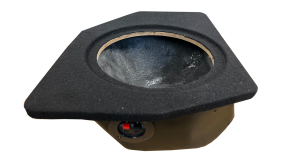

JL AUDIO 13TW5v2-2

13.5-inch (345 mm) Subwoofer Driver, 2 Ω

Groundbreaking large woofer performance with only 67mm of mounting depth.

This unique subwoofer driver is yet another example of JL Audio’s commitment to engineering innovation. Their thin-line woofer technology compresses the architecture of the JL Audio 13TW5v2-2 using a “concentric tube” structure that supports the oversized voice coil and the suspension attachments. This permits placing the large motor structure much further forward in the speaker than with conventional designs while maintaining excellent linear excursion capability and mechanical stability.

In keeping with its “tight-spaces” mission, the JL Audio 13TW5v2-2 is also optimised for enclosures that are far smaller than most 12-inch woofers require and only a bit larger than the air space needs of a typical small-box 10-inch woofer. We even designed the mounting system to allow it to fit in the same footprint as a standard 12-inch woofer.

Deep, powerful and accurate bass is now possible in the most challenging installation applications.

JL Audio couldn’t leave the ultimate thin woofer alone... they had to make it even better.

Their patented thin-line woofer technology compresses the architecture of the JL Audio 13TW5v2 using a “concentric tube” structure that supports the 7-inch diameter voice coil and the suspension attachments. This permits the placement of the large motor structure much further forward in the speaker than with conventional designs, while allowing excellent linear excursion capability and mechanical stability.

To unleash even more performance from this technology, the v2 improves upon the original JL Audio 13TW5 with 13% greater linear excursion capability. The cast alloy chassis has also been modified for greater strength and the redesigned motor now features an annular vent. The v2 is also available in single 2-ohm and single 4-ohm voice coil versions to fit a wide range of applications.

In keeping with its “tight-spaces” mission, the JL Audio 13TW5v2 is optimised for enclosures that are far smaller than most 12-inch woofers require and only a bit larger than the air space needs of a typical, small-box 10-inch woofer. The mounting system is designed to fit in about the same footprint as a typical 12-inch woofer.

The JL Audio 13TW5v2 is best used with amplifier power in the 250W - 600W range and is optimised to operate in a 0.80 cu. ft. (22.7 l) sealed enclosure. Detailed enclosure recommendations can be found in the "Specifications" tab.

Never has such high-quality sub-bass been possible in the most challenging installation applications.

Dynamic Motor Analysis - DMA Optimized Motor

Summary:

JL Audio's proprietary Dynamic Motor Analysis system is a powerful suite of FEA-based modelling systems, first developed by JL Audio in 1997 and refined over the years to scientifically address the issue of speaker motor linearity. This leads to vastly reduced distortion and faithfully reproduced transients... or put simply: tight, clean, articulate bass.

Detailed Information:

Since 1997, JL Audio has been at the forefront of Finite Element Analysis-based modelling of loudspeaker motors and suspensions. This research is aimed at decoding what we refer to as the "Loudspeaker Genome"... a project aimed at understanding the true behaviour of loudspeakers under power and in motion. A major component of this integrated system is DMA (Dynamic Motor Analysis). Starting with the 15W3 and the W7 Subwoofers in the late 1990's and early 2000's, DMA has played an important role in the design of all JL Audio woofers sold today, including our component woofers.

DMA is a Finite Element Analysis (FEA)-based system, meaning that it takes a large, complex problem, breaks it down into small solution elements for analysis and then assembles the data to form an accurate, "big-picture" solution. DMA's breakthrough is that it actually considers the effects of power through the coil as well as coil/cone position within the framework of a time-domain analysis. This gives us a highly accurate model of a speaker's actual behaviour under real power, something that the traditional Thiele-Small models or other low-power measurements cannot do. Because DMA does not rely on a steady-state model, it is able to consider shifts in the circuit elements being analyzed. These modelling routines are intense, requiring hours to run for a whole speaker.

DMA is able to analyze the real effects of fluctuating power and excursion upon the magnetic circuit of the motor, specifically the dynamic variations of the "fixed" magnetic field. This delivers intensely valuable information compared to traditional modelling, which assumes that the "fixed" field produced in the air gap by the magnet and the motor plates is unchanging. DMA not only shows that this "fixed" field changes in reaction to the magnetic field created by current flowing through the voice coil, but it helps our engineers arrive at motor solutions that minimize this instability. Analyzing this behaviour is critical to understanding the distortion mechanisms of a speaker motor and sheds light on the aspects of motor design that determine truly linear behaviour:

- Linear motor force over the speaker's operational excursion range

- A consistent motor force with both positive and negative current through the coil

- Consistent motor force at varying applied power levels

Our ability to fully analyze these aspects of motor behaviour allows our transducer engineers to make critical adjustments to motor designs that result in extremely linear, highly stable dynamic loudspeaker motor systems.

The payoff is reduced distortion, improved transient performance and stellar sound quality.

Floating Cone Attach Method - FCAM™

Summary:

This assembly technique, conceived by JL Audio, ensures proper surround geometry in the assembled speaker for better excursion control and dynamic voice coil alignment.

Detailed Information:

JL Audio's patented FCAM™ technology is an innovative method of bonding the surround/cone assembly to the voice coil former/spider assembly. This feature helps ensure concentricity of the surround, spider and voice coil without torquing the suspension to achieve it. This allows for the inevitable, slight variations in production part dimensions without having them negatively impact the integrity of the suspension and coil-centring at high excursions.

Tab-Ear Frame Design

Summary:

This frame design feature facilitates mounting the Subwoofer in tight spaces.

Detailed Information:

By employing a tab-ear mounting system, the driver's overall outside dimensions are reduced, permitting it to be mounted in a space that is very similar to that required by the next smaller round woofer frame.

In this example, the “Tab-Ear” frame design allows a 13TW5 13.5-inch driver to fit in a space only slightly larger than a conventional 12-inch woofer requires (only 0.44 in. / 11.2 mm bigger)

Concentric Tube Suspension

Summary:

Our Concentric Tube Suspension™ technology delivers unprecedented excursion in a low-profile woofer.

Detailed Information:

The biggest challenge in any low-profile woofer design is to create enough mechanical clearance for the speaker to generate enough excursion to meet its output and low-frequency extension goals. Since these goals were very ambitious in the development of JL Audio's low-profile woofers, achieving them required the development of a new suspension architecture.

JL Audio's solution employs a moulded structure that spans over the edge of the motor system, supporting the spider on the outside of the motor's boundaries and the large diameter voice coil on the inside. The large diameter voice coil permits the magnet to sit inside it, rather than surrounding the coil as is typical in most woofers.

The concentric tube structure and the elimination of a conventional top-plate help JL Audio place the motor system higher up into the cone body's space to further compress depth, while still permitting excellent mechanical excursion.

Built-in U.S.A. with Global Components

Summary:

JL Audio's Miramar, Florida loudspeaker production facility is one of the most advanced in the world.

Detailed Information:

At a time when most audio products are built overseas, JL Audio’s commitment to in-house loudspeaker production continues to grow. To pull this off in a competitive world market, their production engineering team has created one of the world’s most advanced loudspeaker assembly facilities and established a global network of quality component suppliers who build to our specifications. This, combined with their commitment to state-of-the-art assembly technology, allows their skilled workforce to efficiently build JL Audio products to extremely high-quality standards, right here in the U.S.A.

Since most of our premium loudspeakers incorporate proprietary, patented technologies requiring specific assembly techniques, we find it vital that the people who designed them have close access to the people manufacturing them. The following JL Audio products are built in our Miramar, Florida factory, with global components:

- Subwoofers: W7, W6v3, TW5v2, TW3, TW1, W3v3

- Enclosed Car Subwoofers: Stealthbox®, PowerWedge™, ProWedge™, H.O. Wedge™ & MicroSub™ Enclosed Subwoofers

- Marine Loudspeakers, Marine Subwoofers and Marine Enclosed Loudspeakers

- Home Subwoofers: Dominion™, E-Sub, Fathom® and Gotham®

Reviews

There are no reviews yet.